Subtotal $0.00

Selecting the right impact socket set is a long term investment on your efficiency, safety and productivity. It is not just another common buy. From being a home repair contractor to a professional auto mechanic or even a DIY homeowner, having the right impact sockets enhances your work setting. By understanding the components that make up a great impact socket set, you will be in a position to select the right one that will meet your specific needs, as well as one that is durable, and one which will afford you optimum results depending on the tasks that it is to handle.

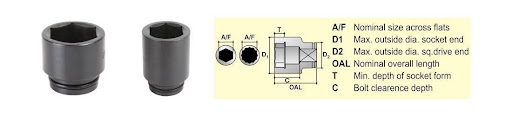

1.Understanding Impact Sockets: The Basics

Impact sockets are made for the high force that is recently being used by pneumatic tools and impact wrenches. Compared to chrome vanadium sockets, these robust accessories are manufactured from high strength materials that can withstand shock, abrupt severe torque without being bent or distorted. Endurance to the shock and vibrations that accompany the use of power tools: There is a significant difference in the two because the walls of impact sockets are stronger while their heat treatment and metallurgy are better than those of standard sockets.

2.Material Matters: Selecting the Right Socket Composition

A significant segment that influences impact sockets operational capacity, durability and overall utility, is the matter of the impact sockets. Indeed, in manufacturing of impact sockets today, Cr-MO steel remains the industry choice because of this material’s incredible strength, flexibility and prolonged durability. They both show that this specific alloy is ideal for these strenuous uses due to the fact that it has superior impact toughness than chrome vanadium steel.

3.Size and Compatibility: Matching Sockets to Your Tools

Selecting impact sockets that work flawlessly with your current tools is essential for both safety and optimum performance. Standard drive sizes for impact socket sets are 1/4″, 3/8″, 1/2″, and 3/4″. Each size is intended for a particular purpose and tool compatibility. The socket’s torque capacity is determined by the drive size; the most common and adaptable drive size among experts is 1/2″. When choosing a set, take into account the variety of tools you now own and project your future requirements.

4.Durability and Construction: What to Look For

The quality of an impact socket set’s manufacture sets great tools apart from mediocre ones. Superior impact sockets include strong external designs that can tolerate repeated high-stress applications, smooth interior walls, and precisely machined surfaces. Seek sockets with low surface flaws, smooth manufacturing procedures, and strengthened corners. Durability is greatly influenced by heat treatment; sockets that have received the right heat treatment have improved molecular structure that makes them more resistant to chipping, cracking, and deformation.

5.Performance Considerations: Torque and Impact Resistance

When assessing impact socket sets, performance measurements are essential, with impact resistance and torque capacity being the main factors. Depending on their size and particular design, professional-grade sockets can normally withstand torque ranges between 500 and 1500 ft-lbs. Determining the proper performance specifications is aided by knowing your usual work requirements.

Conclusion

The process of choosing the best spline impact socket supplier is complex and requires careful evaluation of several variables. You can make an informed choice that improves your professional capabilities by being aware of the material composition, performance characteristics, compatibility requirements, and maintenance requirements. A good impact socket set is more than just a set of tools; it’s a calculated investment in your skill, output, and reputation in the workplace.